Transformative Impact of Flap Disc Making Machines: Lowering Costs and Widening Access

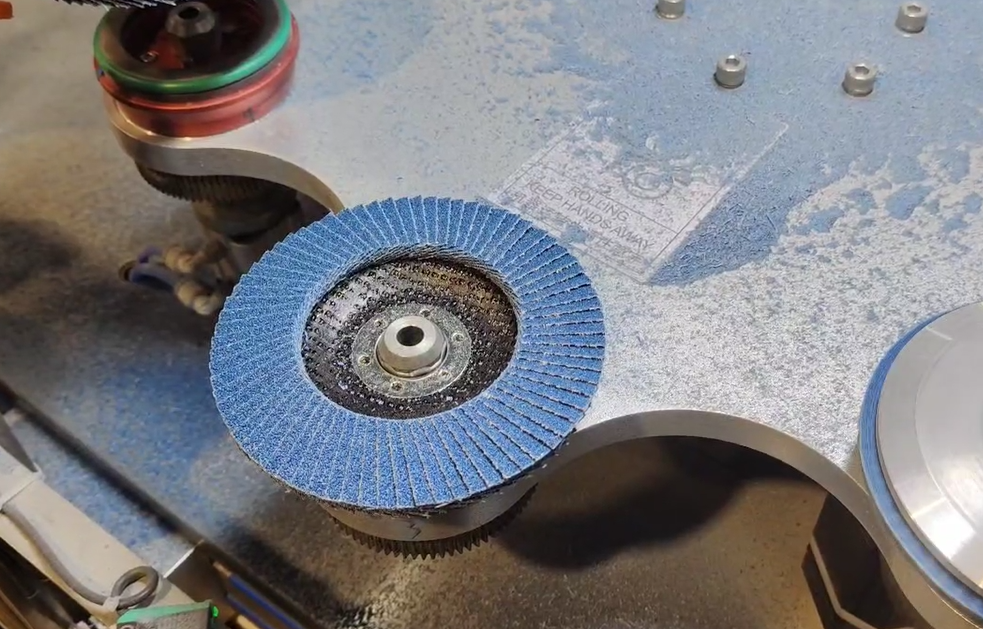

The introduction of flap disc making machines has reshaped the landscape of abrasive production, resulting in significant cost reductions and improved accessibility for consumers and industries alike.

Comparing prices from around the year 2000 to the present day, the dramatic drop in flap disc costs stands as a testament to the influence of these automated machines. Previously, prices were considerably higher, but the advent of fully automatic flap disc making machines streamlined production, slashing operational expenses.

China's entrance into the manufacturing sector for these machines has democratized access, enabling a wider range of producers to benefit from cost-efficient manufacturing methods. Moreover, the decline in raw material expenses, notably abrasive cloth and crucial flap disc adhesive components, has further contributed to lowering overall costs.

The impact extends beyond the industry realm; everyday consumers also benefit. The versatile application of flap discs in various sectors, such as automotive and metalworking, has led to cheaper, high-quality products. This affordability has subsequently reduced production costs for businesses in these sectors.

Companies like Taino, a leading Chinese manufacturer of flap disc making machines, are committed to innovation and service excellence. They aim to support clients with post-sales services, emphasizing their dedication to being a reliable partner in production endeavors.

The evolution of flap disc manufacturing, driven by technological advancements and market forces, has resulted in more affordable products and expanded accessibility. The combination of reduced costs and improved availability underscores the profound impact of flap disc making machines on industries and consumers alike.