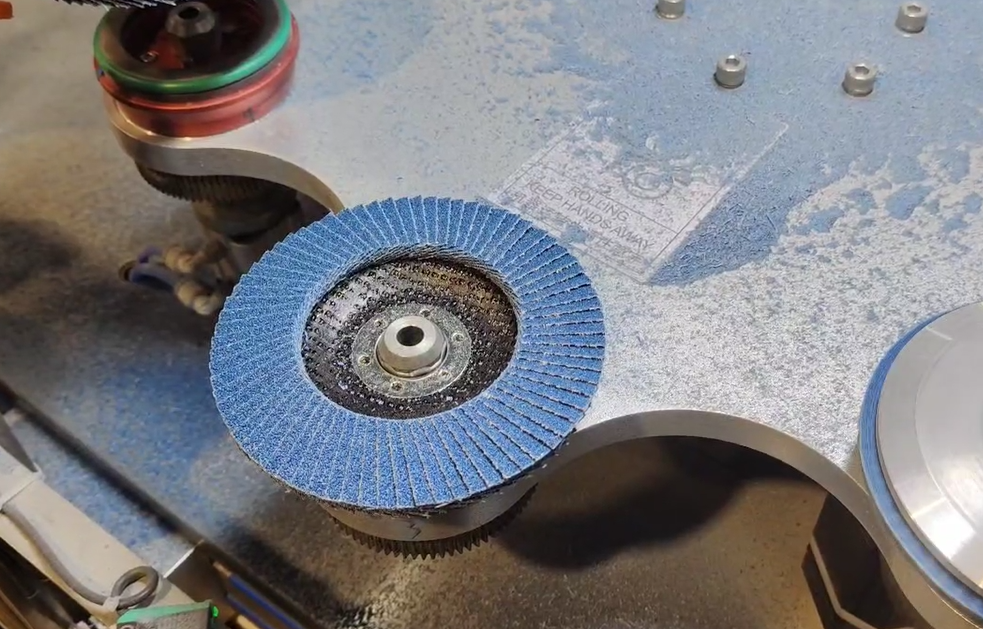

Unveiling Precision and Performance: Fully Automatic Flap Disc Machine's Technical Mastery

Article Body: Mastering Technical Excellence The Fully Automatic Flap Disc Machine redefines technical finesse in manufacturing. Its eight-station turntable, coupled with dual six-station loading turntables, underscores its efficiency, producing between 700 to 1100 pieces per hour.

Technical Specifications: A Symphony of Innovation

With dimensions optimized for workspace efficiency, this machine leverages a combination of pneumatic and electric power sources. Its precise gluing system, adjustable from 3 to 30g with a precision of ±0.1g, ensures meticulous adhesive application across various base sizes and materials.

Meticulous Control Systems and Adaptability

Powered by a sophisticated motion control system, it employs relative positioning, cam principles, and pendulum theories for precise operation. The intelligent constant temperature water circulation system in the adhesive feeding system enhances adaptability to different glue types.

Versatility and User-Friendly Interface

Operators will appreciate its adaptability to diverse base sizes, ranging from Φ75mm to Φ180mm, and compatibility with T27/T29 models. The machine’s user interface allows for seamless adjustments, with one operator able to manage two units effortlessly.

Conclusion:

The Fully Automatic Flap Disc Machine epitomizes technical innovation in manufacturing. Its meticulously engineered design, precision control systems, and adaptability mark a new standard in the industry, empowering manufacturers to achieve unmatched efficiency and quality in production.