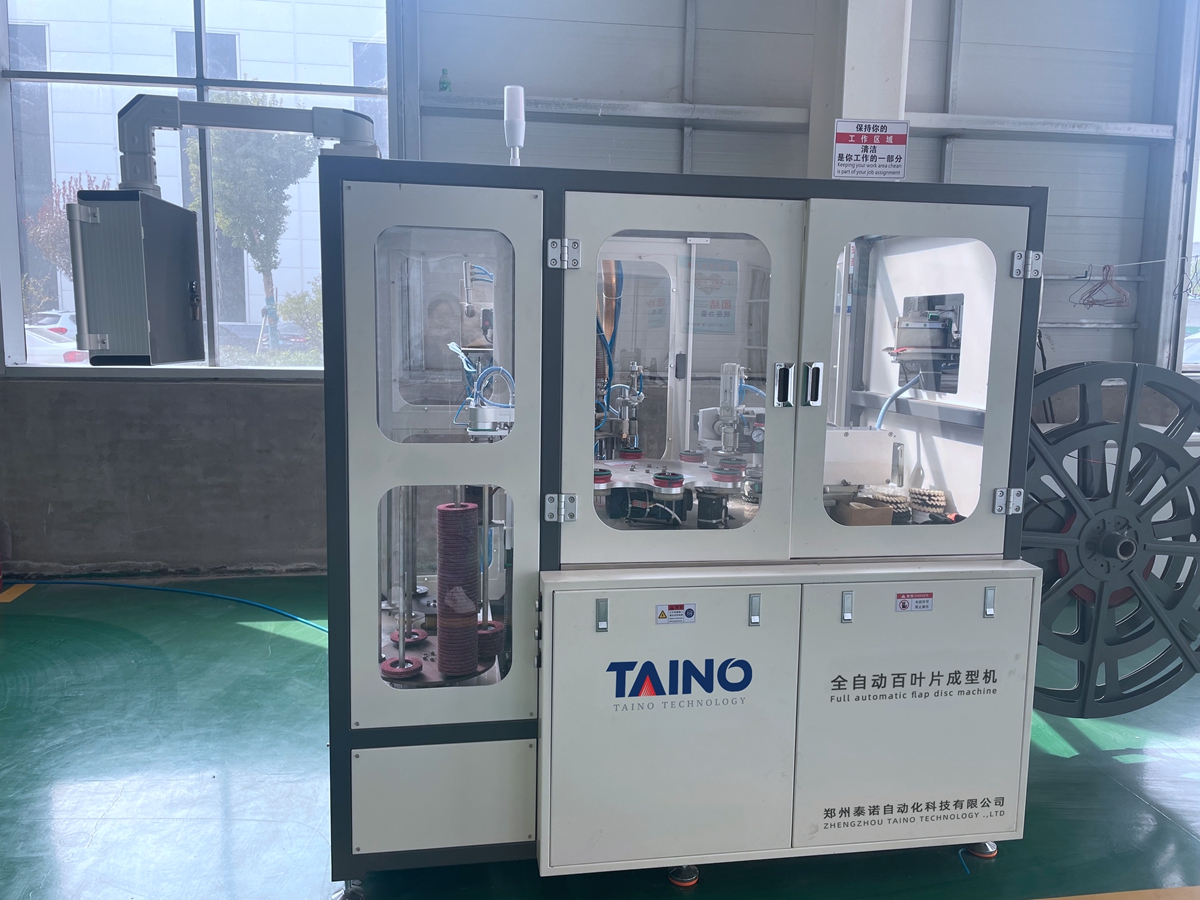

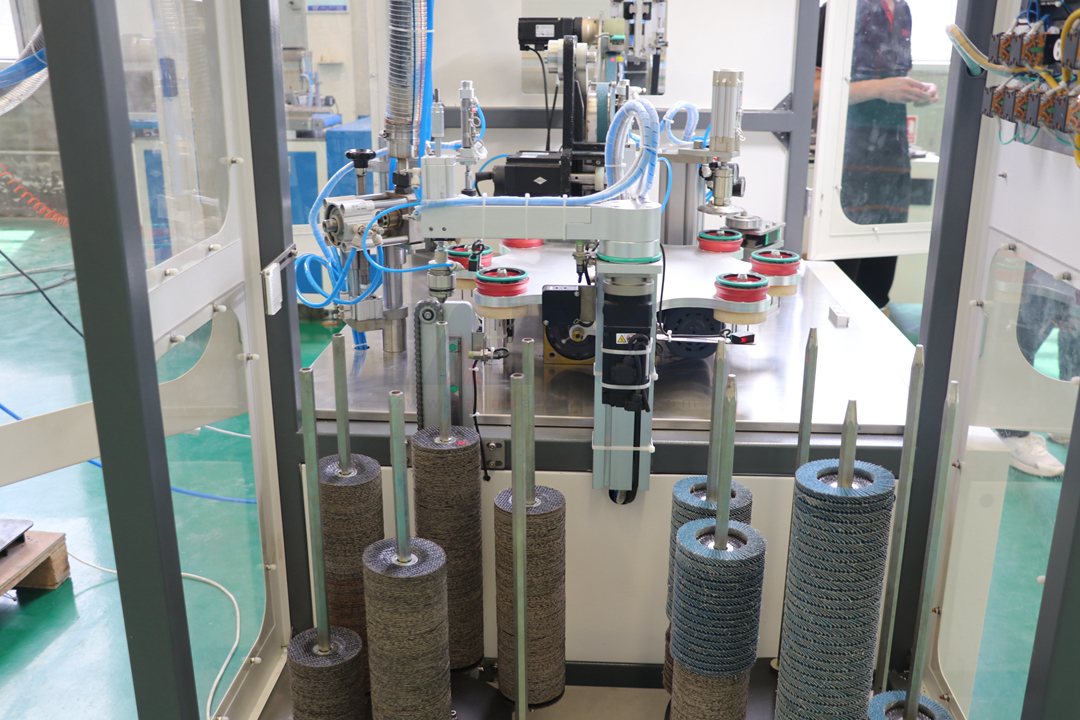

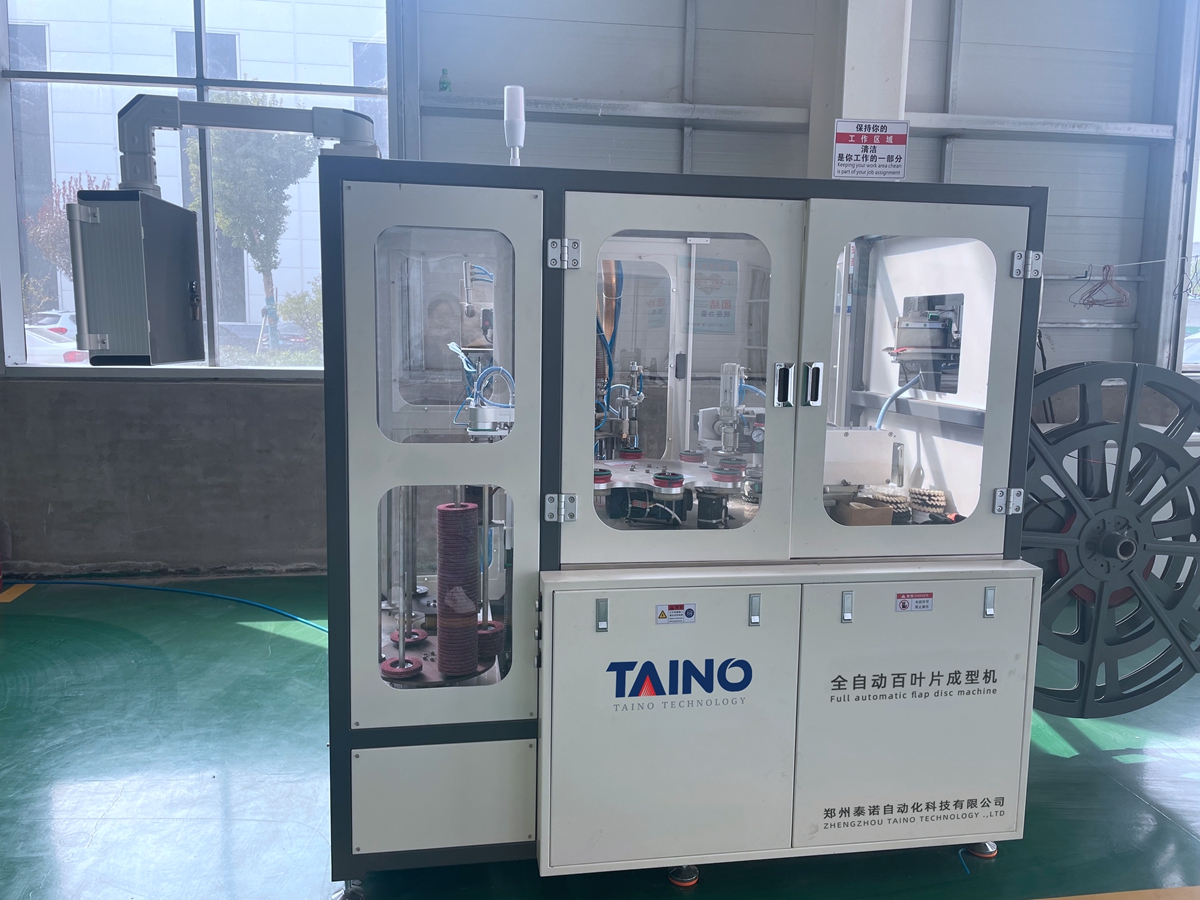

Full automatic flap disc machine is the automated equipment to produce flap disc, which can realize auto load backing pad, detection of backing pad, quantitative glue, blanking and slide arranging, shaping.

|

Product |

Full automatic flap disc machine |

|

model |

TNWQ-180 |

|

Main body size |

1620*1620*2100(mm) |

|

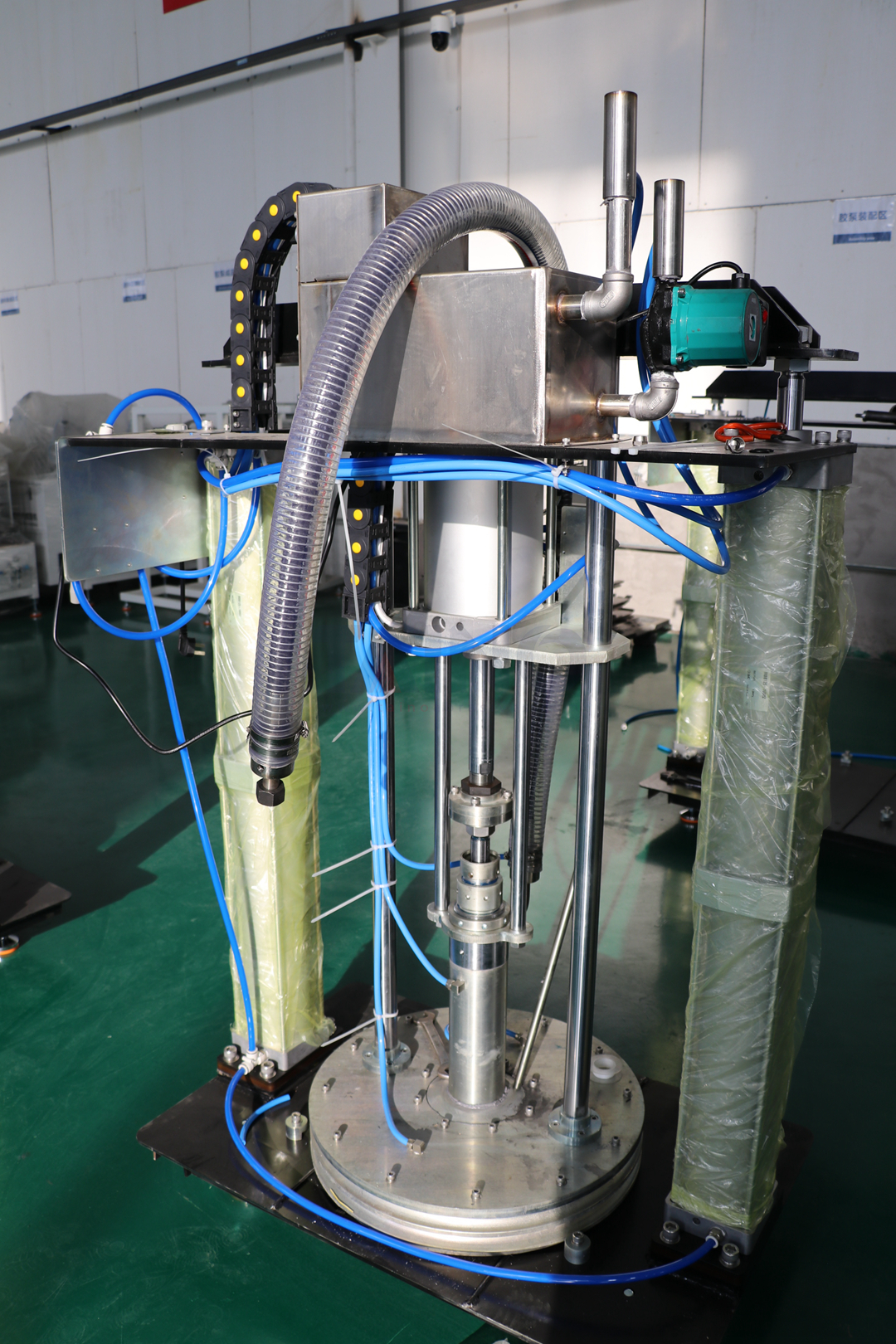

Gule pump size |

1320*820*1820(mm) |

|

Feeding system size |

1050*750*2170(mm) |

|

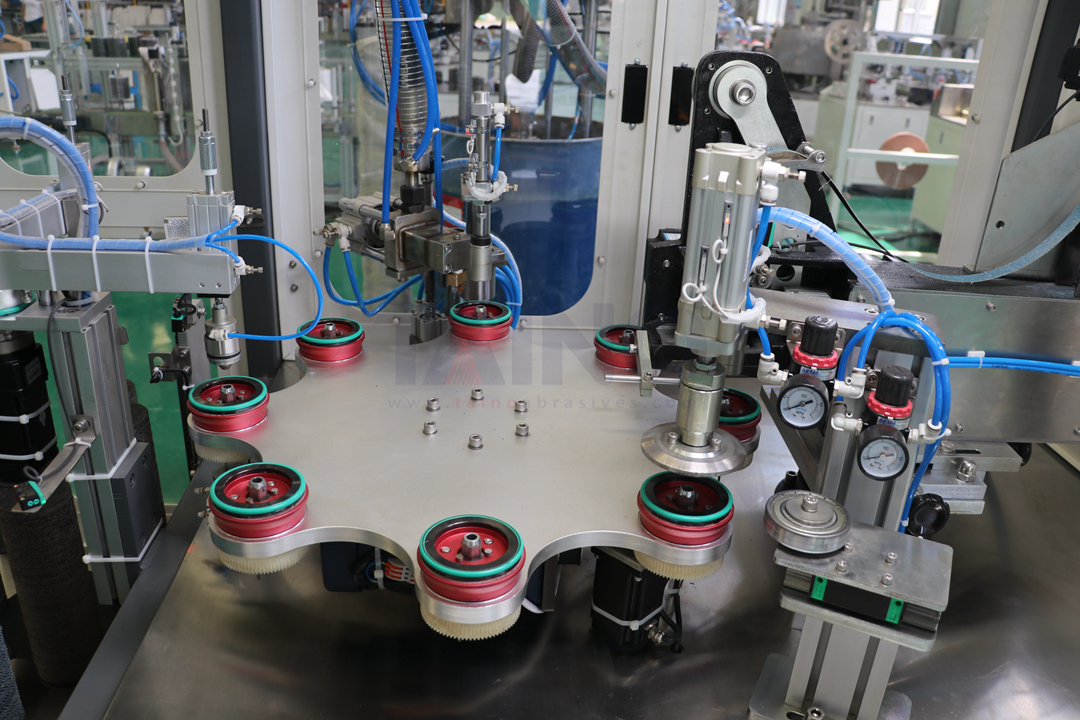

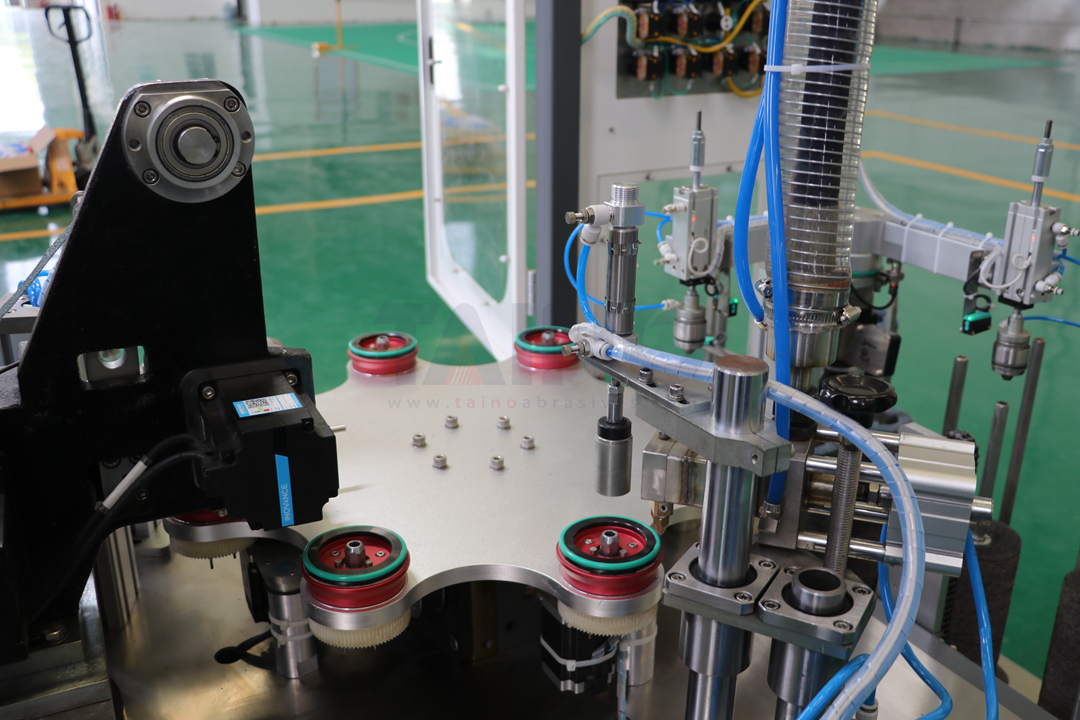

Station of plate |

8 |

|

Voltage |

380V 50HZ |

|

Power |

7kw |

|

Glue pump |

300kg or 30kg |

|

Glue coated |

3-30g(can be adjusted) ±0.1g |

|

Flaps quantity |

Can be set at any angle of 360° |

|

Output |

600-800p/hours |

|

Backing type |

Φ75mm~Φ180mm 、 T27/T29 |

|

Backing material |

Fiber glass or plastic |

|

Belt width |

11mm-40mm |

|

Flap length |

14mm-22mm |

|

Motor |

Panasonic servo |

|

PLC |

Delta |

|

Glue feeding system |

Airtac cylinder+Smart thermostat system |

Machine main characters

New generation full automatic flap disc machine adopts brand new design concept,many parts were optimized compared with former generation,the whole structure is more precise and more stable,thus flap disc stability and durability is effectively improved.Taino full automatic flap disc machine can automatically upload backing,detect backing,quantitatively feeding,flap cutting and setting,shaping and automatically download finished flap discs with high automation.Flap disc quality is very good and under control.