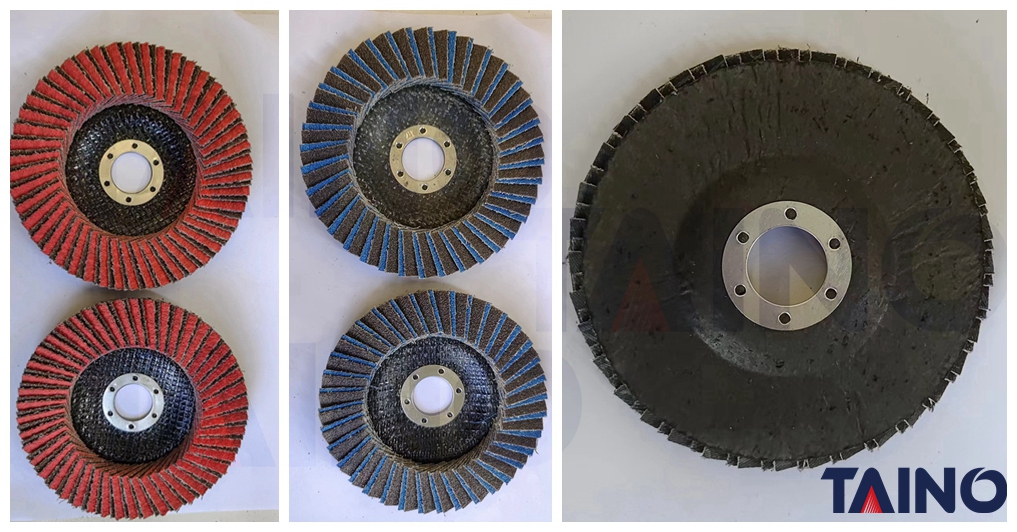

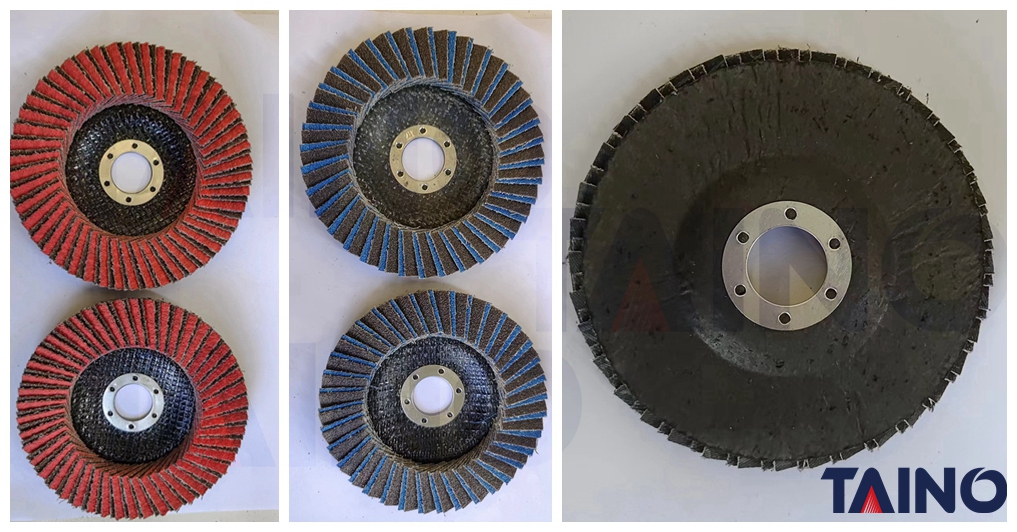

Double Leaves Flap Disc Making Machine by Taino Abrasives, a cutting-edge apparatus designed to revolutionize the production of Double Leaves Flap Discs and Combined Flap Discs. This machine boasts an exceptional capability to concurrently incorporate two types of abrasives, enhancing production efficiency and ensuring remarkable stability. Distinguishing itself from conventional Flap Disc Machines, this innovation features dual feeding racks, accommodating two distinct abrasive materials or other raw components.

The resulting Double Leaves Flap Discs and Combined Flap Discs surpass their counterparts in durability and extended lifespan, ideal for proficiently polishing weld seams and catering to specialized applications. This automated equipment facilitates seamless processes from automatic substrate loading, substrate (backing plate) detection, precise adhesive application, punching and cutting, shaping, to the automated retrieval of finished products.

The advent of Taino Abrasives' Double Leaves Flap Disc Making Machine signifies a milestone within the industry, significantly reducing manufacturing costs for flap disc producers while amplifying their competitive edge.

The Double Leaves Flap Disc market exhibits vast potential, specifically tailored for effective weld seam surface polishing, securely bonding abrasive cloth with specialized adhesives, rendering it highly resilient. With heightened productivity, it is perfectly suited for grinding stainless steel, high-alloy steel, low-carbon steel, and ferrous metals.

Key Advantages:

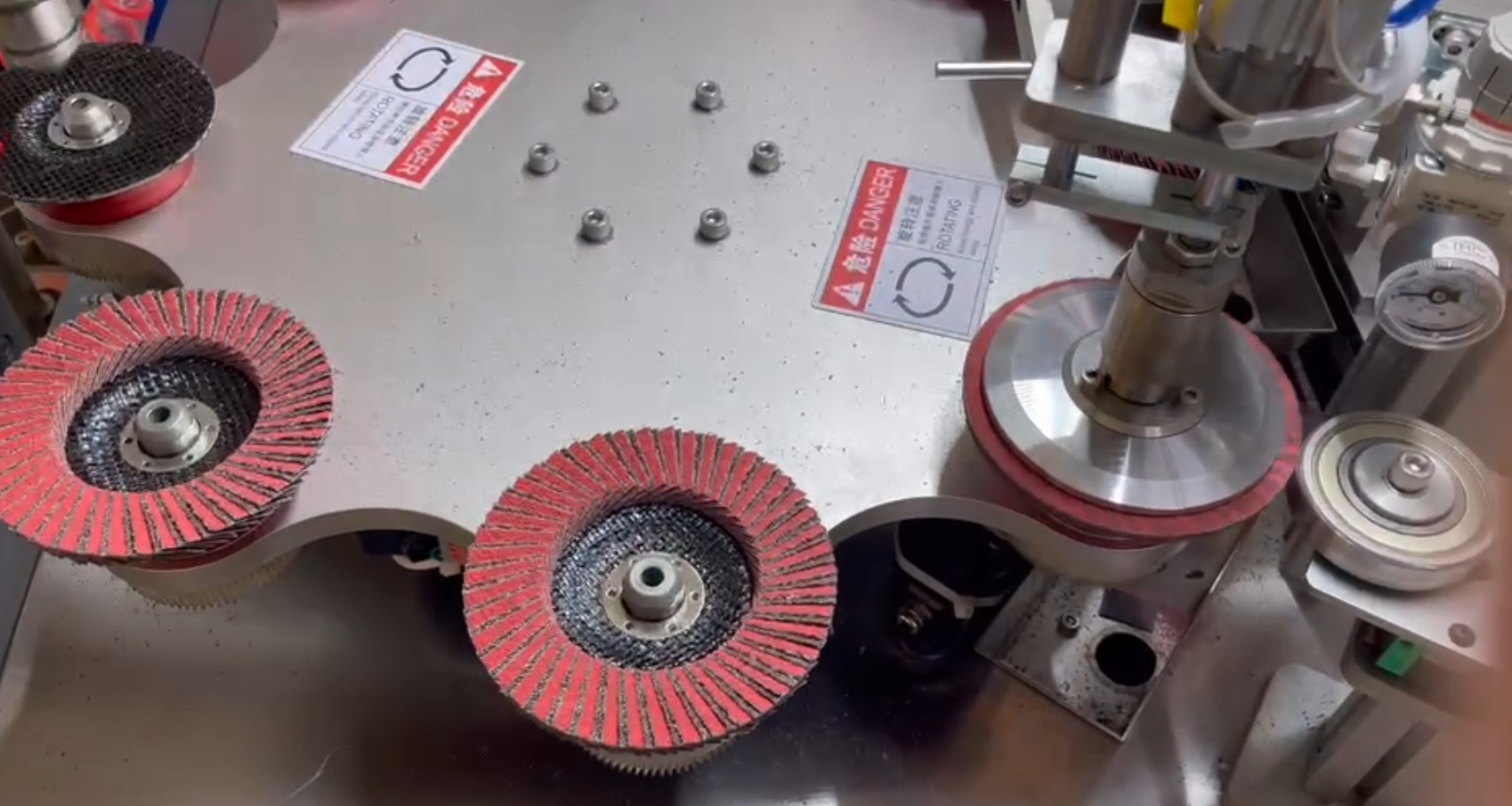

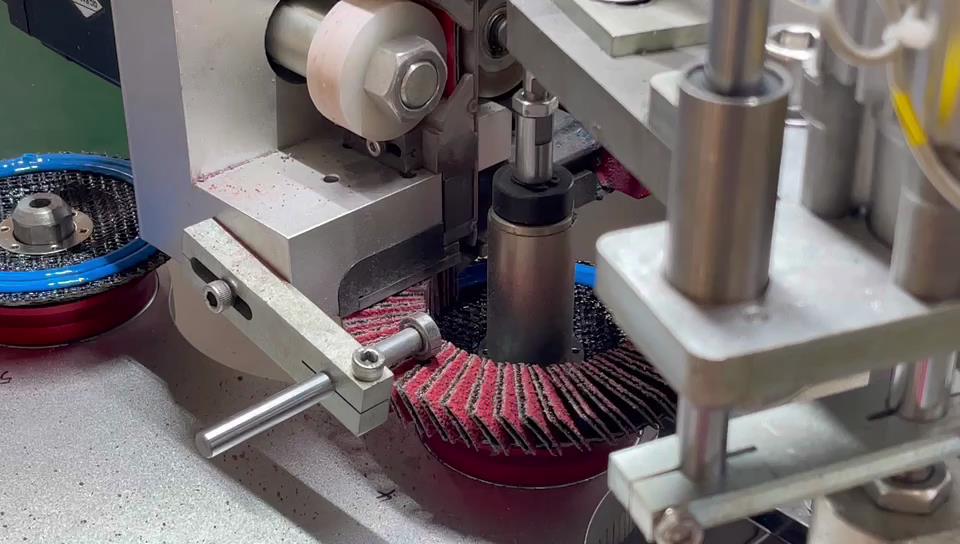

1. Overcoming industry challenges, this machine mechanizes the production of Double Leaves Flap Discs,Combined Flap Discs and allows simultaneous integration of two raw materials, substantially reducing production costs. Featuring a PLC control system, it attains exceptional automation, enabling a single operator to manage multiple units, liberating labor and cutting down on workforce expenses.

2. Equipped with a rotary multi-station turntable mechanism, ensuring stable station transitions, precise positioning, and high efficiency, yielding between 800 to 1100 pieces per hour.

3. Accommodates various substrate sizes using high-strength aluminum alloy materials, ensuring stability, durability, and facilitating convenient blade loading and unloading.

4. The adhesive application system incorporates an internal water circulation temperature control system, offering adaptability to multiple adhesive materials.

5. Utilizes imported photoelectric switches during the layout process, automatically detecting substrate and abrasive cloth presence, ensuring stability and precision by filtering out positions lacking substrates or adhesive.

6. Adjustable precision in the angle and length of disc placement, equipped with a calibrated translatable head adjustment for accurate and efficient operation based on displayed parameters.

7. Achieves high material utilization rates with freely adjustable bonding agent and abrasive belt distribution.

8. Exhibits an exceptionally low defect rate once machine parameters are set, boasting industry-leading yield rates.

Specifications:

Incorporating cutting-edge technology, meticulous design, and unparalleled efficiency, the Double Leaves Flap Disc Making Machine by Taino Abrasives stands as an epitome of innovation, transforming production processes and elevating the standards within the industry.

YouTube video address:

https://www.youtube.com/watch?v=7QAgjdaov7g

YouTube video: