The TN-TPJ125/180 Intelligent SMT Machine, manufactured by Taino Abrasives, is a state-of-the-art product developed through the integration of advanced experience in the automation industry and current market demands. This machine is designed to achieve high levels of automation, allowing for the automatic placement of substrates, substrate detection, quantitative glue application, chip cutting and placement, shaping, and automatic retrieval of finished products. It is characterized by the following features and technical parameters:

Features:

- High Automation: The machine's PLC control and rotating multi-station turntable mechanism enable high automation, allowing a single operator to handle multiple units, thus saving labor costs.

- Versatility and Durability: The machine can accommodate various substrate models, and its high-strength aluminum alloy material ensures stability, durability, and convenient blade loading and unloading.

- Precision and Efficiency: The machine allows for precise and adjustable chip placement angles and lengths, with the head adjustment equipped with a scale for accurate and efficient operation.

- Gluing System: It is equipped with a dispensing system that can be customized according to specific requirements.

Technical Parameters:

- Efficiency: 6-10 seconds per piece

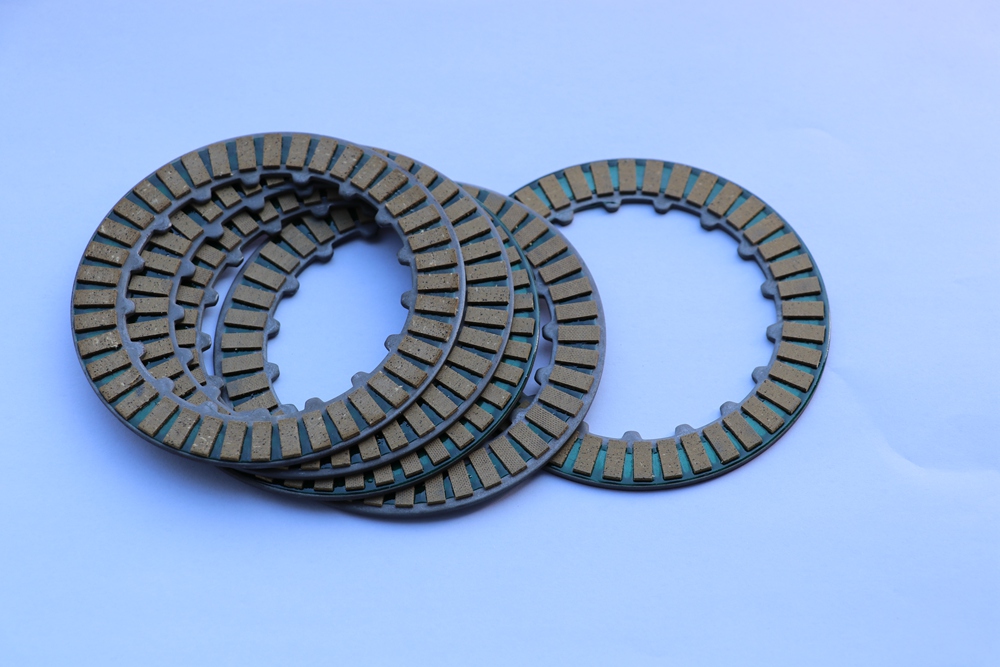

- Production Models: Outer diameter 80-125/125-180

- Changeover Time: Not exceeding 2 hours

- Equipment Appearance: Aluminum alloy profile, acrylic plate, steel base

- Safety: The machine is equipped with safety protection during operation

- Yield: The bonding strength has a yield rate of over 98%, with no detachment

- Equipment Dimensions: 1100-1350-1560

- Component Transfer: The loading and unloading are carried out by a rotating warehouse

- Operation Mode: HMI (Human-Machine Interface)

The TN-TPJ125/180 Intelligent SMT Machine is suitable for a wide range of industries, including automotive, motorcycle, electric, machinery, and home appliances. It is designed to streamline the production process, improve speed, and enhance efficiency, making it an ideal solution for automated production processes.The machine's development involved significant investment in terms of both capital and technology, along with extensive testing and refinement, resulting in a substantial increase in chip placement speed and efficiency.The product is a testament to Taino Abrasives' commitment to innovation and meeting the evolving needs of the market, making it a valuable addition to the automated manufacturing landscape.