-

Size of main-body1310mm*830mm*1560mm

-

Size of Glue pump1100mm*650mm*1500mm

-

PlateEight

-

Size of feed belt1000mm*400mm*1450mm

-

Speed800-1100pcs/hour

-

Voltage3phase4wire 380v+N 50HZ/60HZ

-

Power5-7kw according to different configuration

-

MotorImported Panasonic servo motor

-

Power supplyPneumatic,electric

-

Glue pump specifications280KG

-

Glue coated3-30g(can be adjusted) +0.1g

-

Flap quantityCan be set at any angle of 360(20-200pcs/product)

-

Size of backing padφ75mm~φ180mm、T27/T29

-

Belt widthDouble flap,flap width 20mm-40mm

-

Backing materialFiberglassiron,plastic

-

Flap length11mm-25mm

-

Motion control systemRelative positioning + camprinciple + pendulum principle

-

Glue systemConstant voltage conversion+Intellgentthermostatic water circulation system

-

OperationOne people

- 1.PLC control system,high degree of automation, single person can operate multiple equipment, free labor, save labor costs for you.

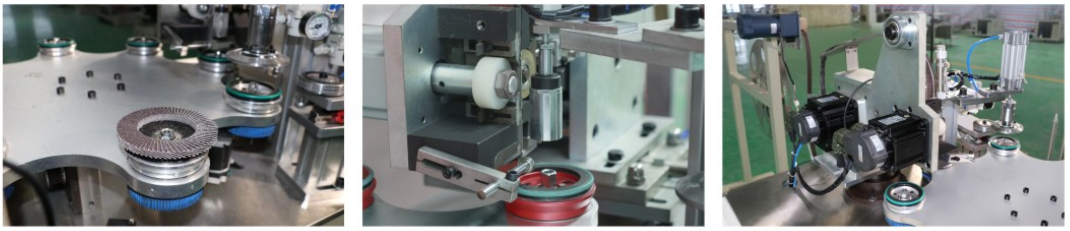

- 2.Equipped with rotary multi-station turntable mechanism, stable station conversion, accurate positioning, high efficiency, each hour can produce 8001100 pieces.

- 3.Can be placed in a variety of different types of matrix, with high strength aluminum alloy material, stable and durable, convenient loading and unloading blade.

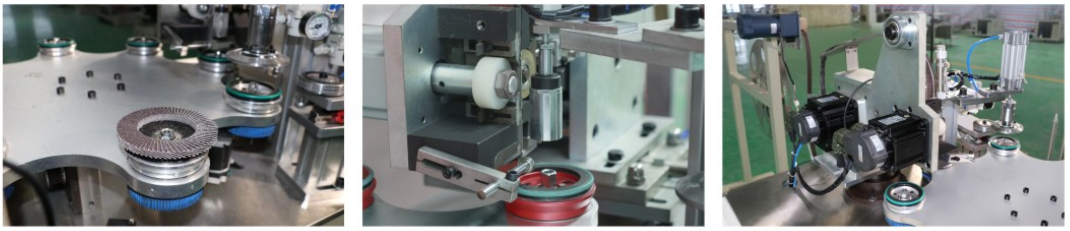

- 4.The glue system adopts the internal water circulation constant temperature control system, reasonable structure suitable for a variety of materials glue.

- 5.The product adopts imported photelectric switch to detect whether the substrate and emery cloth are in the process of the sheet arrangement,and automatically filters the non-substrate station and the non-adhesive substrate, which is stable and accurate.

- 6.The Angle and length of the nose plate are precise and adjustable. The nose adjustrment and translation are equipped with a scale, which can be operated accurately and efficiently according to the display parameters, simple and fast.

- 7.The production material utilization rate is high, the adhesive and sand belt can be set freely.

- 8.Very low defective rate.After the machine parameters are set, the finished product rate is second to none in the same industry

Semi-automatic flap disc machine

The semi-automatic louver forming machine is an automatic equipment for the production of elastic grinding discs. There are automatic equipment for manual placement of the substrate.quantitative gluing, punching and sheeting, and automatic shaping.