-

Size of main-body1200mm*1620mm*1460mm

-

Glue systemHeart glue can be selected automatically

-

Speed400-700pcs/hour

-

Size of feed belt1000mm*400mm*1450mm

-

PlateTen

-

Loading and unloadingturntableEight

-

Voltage3phase4wire 380v+N 50HZ/60HZ

-

Power7KW

-

MotorImported Panasonic servo motor

-

Power supplyPneumatic,electric

-

Glue pump specificationsBase glue/heart glue 30kg

-

Glue coated3-30g(can be adjusted) +0.1g

-

OperationOne peole can operation 2sets

-

Flap quantity45-52-60

-

Size of backing pad52mm-56mm

-

Backing materialFiberglass.iron,Steel paper

-

Belt width24mm-30mm

-

Flap length26mm-28mm

-

Motion control systemRelative positioning + camprinciple + pendulum principle

-

Selection of base glueSingle glue pump 280/30kg;Double glue pump 30kg

-

Selection Heart glueSingle glue pump 280/30kg;Double glue pump 30kg

-

- 1.PLC control system, high degree of automation, single person can operate multiple equipment, free labor, save labor costs for you

- 2.Equipped with rotary multi-station turntable mechanism, stable station conversion, accurate positioning, high efficiency, each hour can produce 400-700 pieces.

- 3.Can be placed in a variety of different types of matrix, with high strength aluminum alloy material, stable and durable, convenient loading andunloading blade

- 4.The glue system adopts the internal water circulation constant temperature control system, reasonable structure, suitable for a variety of materials glue.

- 5.The product adopts imported photoelectric switch to detect whether the substrate and emery cloth are in the process of the sheet arrangement, and automatically filters the non-substrate station and the non-adhesive substrate, which is stable and accurate.

- 6.The Angle and length of the nose plate are precise and adjustable. The nose adjustment and translation are equipped with a scale, which can be operated accurately and efficiently according to the display parameters, simple and fast.

- 7.The production material utilization rate is high, the adhesive and sand belt can be set freely.

- 8.Extremely low defect rate, so that your production more worry.

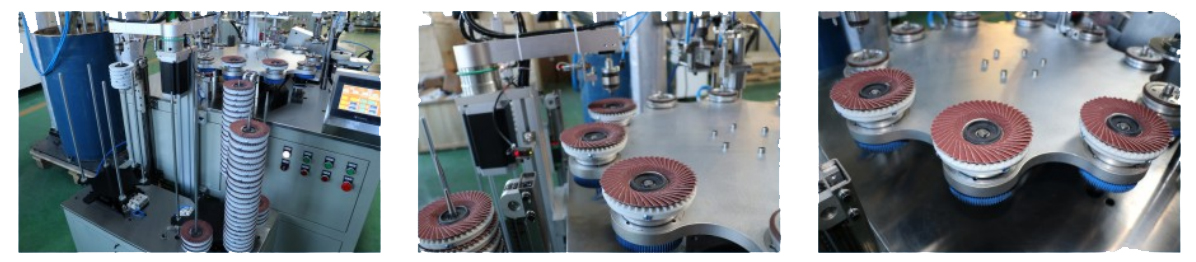

Flexible flap disc machine

The automatic Korean flower butterfly molding machine is a fully automatic equipment for producing Korean elastic grinding discs.It can realize automatic substrate loading, collective inspection,quantitative gluing, punching and arranging, shaping, core glue and automatic finished product automatic equipment.